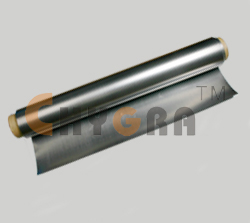

| S4100 EXPANDED GRAPHITE ROLLING (SHEETS) |

| |

|

| |

|

Natural graphite flake is chemically treated to

form Graphite |

| Intercalation Compound. This intercalation

compound is then rapidly heated to decomposition. The result is a

rapid expansion of the particle size. The bulk density of the worm-like

graphite powders is about 0.003g/cc. Then they are formed into graphite

sheets by rolling. |

| |

| Principal applications: |

|

Glands |

|

Gaskets used in flanges, covers of observation

holes, level meters. |

|

Direct attach to the metal surfaces for gas

phase sealing effectively. |

|

Especially the expanded graphite rolls can

be used as a material for automatic producing lines. |

|

| |

| Specification of expanded graphite

rolling |

| Item |

Unit |

Value |

| Tolerance of density |

g/cm3 |

-0.06~+0.06 |

| Tolerance of thickness |

mm |

-0.04~+0.04 |

| Carbon content |

% |

99 |

| Tensile strength |

MPa |

4.5 |

| Compressibility |

% |

>40 |

| Recovery |

% |

>10 |

| Sulphur content |

ppm |

<1100 |

| Chlorine content |

ppm |

<45 |

| Temperature |

°C |

-200~+600 |

|

| |

| Rolling sheet size: |

| Density(g/cm3) |

Length(m) |

Width(mm) |

Thickness(mm) |

0.8(or)

1.0(or)1.1 |

30,50,80,or other size |

<=1500 recommend use 1000mm |

0.2~1.0 recommend use 0.2, 0.25,0.3,0.4,0.5,0.6,0.75,0.8mm |

|

| |

| Special specification can be production

for require. |

| |

|

| |